If you’ve been 3D printing for a while, chances are you’ve already faced this issue — that one print that came out stringy, brittle, or just weak for no reason. You change slicer settings, swap nozzles, and maybe even blame your printer. But the truth? Most of the time, it’s just moist filament.

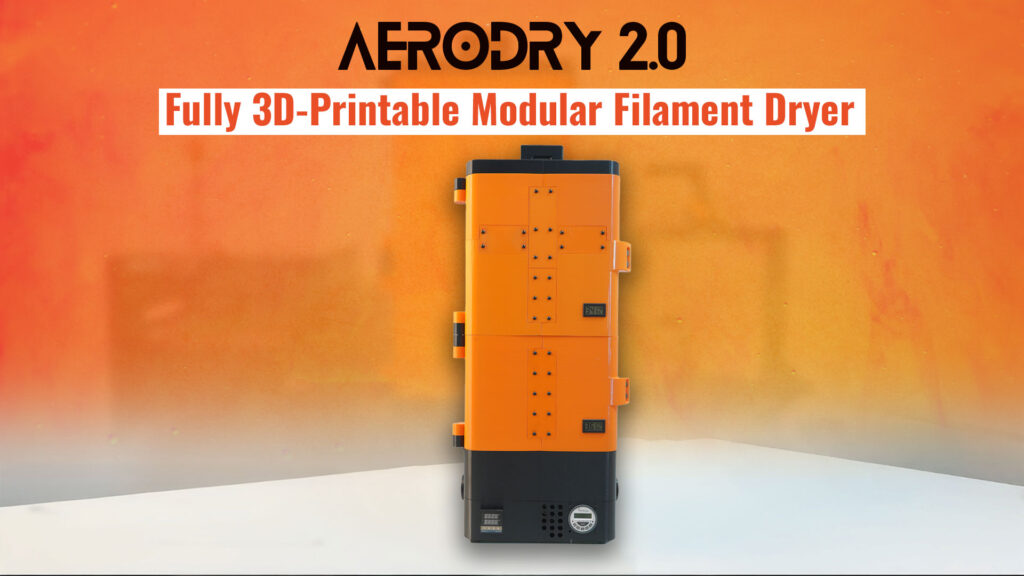

Moisture is the silent killer in 3D printing. And that’s exactly why I created AeroDry 2.0.

This isn’t just another plastic box with a fan and heater inside. AeroDry 2.0 is something I built from the ground up to solve a problem — not just to sell a product. It’s made for makers, designed to be printed at home, and built to actually work. And if you ask me, that’s what makes it the ultimate filament dryer.

Let me break it down.

AeroDry 2.0 is live on Kickstarter — back it now and be one of the first to build your own modular filament dryer.

A Filament Dryer That Grows With You

One thing I hated about most commercial dryers? They’re fixed in size. You can fit one or two spools in them, and that’s it. The day you buy a 3kg or 5kg spool, they become useless.

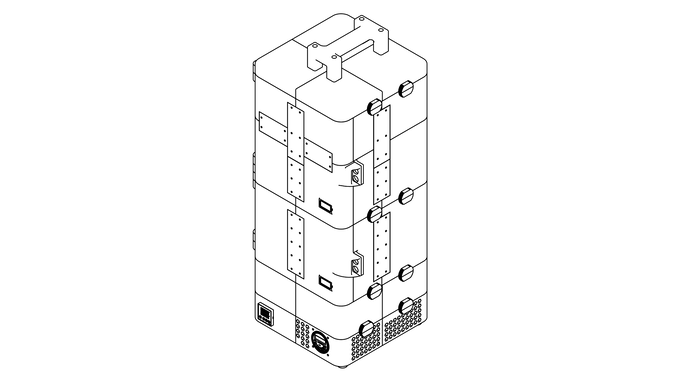

AeroDry 2.0 is different. It’s modular and stackable, which means you can make it as tall as you want. You start with a base unit that holds the electronics, and then just print more chambers and stack them on top.

Got three 1kg spools? Cool, print the 1kg chamber.

Got a 5kg spool? No problem, print the larger one.

Mix and match? Totally fine.

The chambers just bolt together — no tools, no weird fittings. And yes, even the bolts are 3D printed.

Fully Printable, Even the Fasteners

Now here’s the part I personally love. AeroDry 2.0 is almost entirely 3D printable. The chambers, the fasteners, the bolts — everything.

You don’t need to go out and buy a bunch of screws or custom parts. Just download the files, slice them, and print them. It feels like the whole thing was made for people like us — people who enjoy making stuff with their printers.

And when the entire system is built by you, with parts you made, it just hits different. It’s not some random device you bought. It’s yours.

Not Just a Box With a Heater

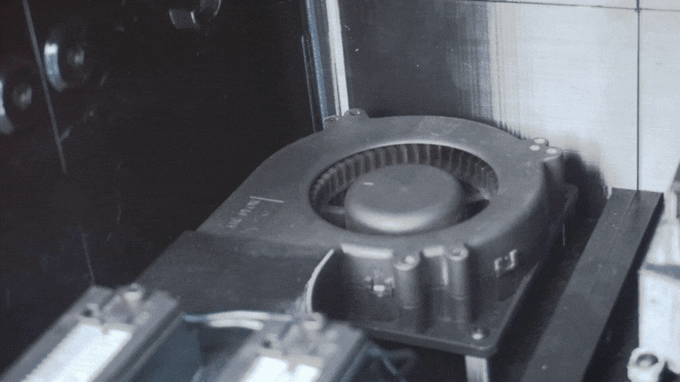

Okay, so let’s talk about what actually makes this a dryer — the heat and the airflow.

I used a PTC ceramic air heater, which is not only efficient but also self-regulating. That means it doesn’t overheat, it doesn’t burn anything, and it’s safe to run for hours.

But heat alone isn’t enough. You need good airflow to move the hot air through the chambers and remove the moisture. That’s where the two 120mm blower fans come in. These aren’t little wimpy fans — they move air like a champ, and they circulate the heat throughout the tower evenly.

And of course, you can control everything with a digital thermostat and timer. Set your temperature, set how long you want it to run, and just let it do its thing. No need to babysit it.

Dry, Store, and Print — All in One

This part might be the most underrated. With AeroDry 2.0, you don’t have to dry your filament and then take it out and store it somewhere else. It’s already in an airtight chamber. You just plug your filament into the outlet and feed it directly into your printer.

Every chamber has a filament outlet, and the whole system doubles as a dry box. So you’re not just drying your filament — you’re keeping it dry during storage and even while printing.

It’s a complete loop. Dry, store, print. No in-between steps.

Track Humidity in Real Time

There’s something satisfying about knowing exactly what’s going on inside the chamber. AeroDry 2.0 includes a real-time humidity sensor in every chamber.

You can glance at the reading and instantly know whether your filament is staying safe or not. If it’s too humid, turn the heater back on. If it’s stable, leave it be. It puts you in control.

Clean Look, Snappy Feel

The doors? They snap shut with magnets. No latches, no tiny clips to break. Just a clean click, and the whole chamber seals shut.

It’s fast, simple, and helps maintain both temperature and humidity inside.

Built for the Workbench, Ready to Move

I also added a carry handle on top, because I know what it’s like to have limited workspace. Sometimes you need to move your dryer around, and with AeroDry, you can.

Even if it’s fully stacked with filament, you can just grab the handle and shift it to a different table. No need to disassemble anything.

Back Aerodry 2.0 on Kickstarter

Why I Made This (and Why It’s on Kickstarter)

Honestly, I made AeroDry 2.0 because I was frustrated with the other options out there.

The commercial dryers were expensive, underwhelming, or only worked for 1kg spools. The DIY ones looked cool but didn’t actually solve the problem. And storing filament in a food container with desiccants wasn’t cutting it for me anymore.

So I built my own. I printed it. I used it. I iterated it. And I realized — this could help a lot of people. So I put it on Kickstarter, because I wanted to share it with the community that made me fall in love with 3D printing in the first place.

Final Thoughts

AeroDry 2.0 isn’t just a tool. It’s a printable, customizable, real solution for anyone who takes filament quality seriously. It’s for makers, by a maker. And if you’ve ever ruined a print because your filament soaked up moisture, you already know why this matters.

You can check it out on Kickstarter right now, and if you like building things with your printer — I think you’ll really enjoy building this.